Beyond the Price Tag: The True Cost of Owning Acrylic Sheets

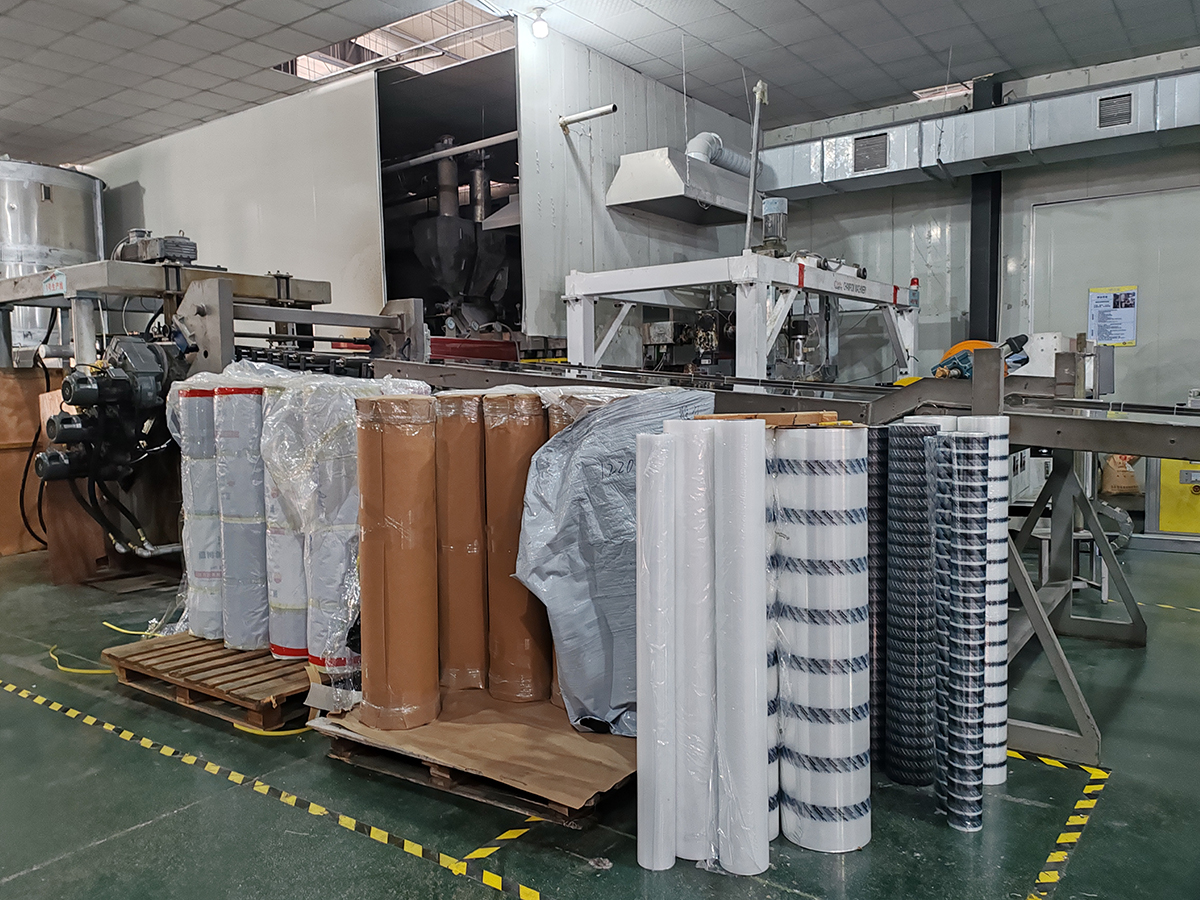

$1.15 available: In StockQuick Overview: Zhejiang Yifang New Materials, with 20 years of production and processing, international standards, and a daily output of 70 tons.

When evaluating the quotation for acrylic sheets, focusing solely on the unit price is like seeing only the tip of the iceberg. Smart procurement experts understand that the true cost is reflected throughout the entire lifecycle of the product. Let us help you make wiser purchasing decisions.

Quality Cost: Invisible Budget Killer

Poor quality acrylic sheets will experience yellowing, brittleness, and other issues within 6-12 months after installation, resulting in expensive replacement costs and brand reputation damage. We use 100% pure new materials for production, ensuring that our products have excellent weather resistance and impact strength. Although the initial unit price may be slightly higher, your product will remain in perfect condition for many years to avoid the hassle of repeat purchases.

Efficiency Cost: Neglected Productivity Loss

Poor tolerance control of boards can lead to installation difficulties and increase labor costs by over 30%. Our CNC production line ensures that the thickness tolerance is controlled within ± 0.1mm and the cutting accuracy reaches ± 0.5mm. This means that your team can quickly complete the installation and invest more time in creating value.

Risk Cost: Hidden Expenses in the Supply Chain

Communication errors, delivery delays, and unprofessional documents can all bring unexpected costs. We have native English speaking customer managers who provide real-time order tracking and professional export document support. Choosing us means you can focus on your core business rather than dealing with supply chain issues.

Want to comprehensively evaluate your procurement choices? Leave a message now to access our 'Acrylic Sheet Total Holding Cost Calculator' and help you make the wisest purchasing decisions!

| Compositions | pet、ps、acrylic |

| Styles | 1.22*2.44*3/Customization of various specifications and sizes |

| manufacturer | Yifang |

related products

FREE SHIPPING

Free shipping on all UK orders

FREE EXCHANGE

30 days return on all items

PREMIUM SUPPORT

We support online 24 hours a day

BLACK FRIDAY

Shocking discount on every friday