Is your acrylic sheet production factory a bottleneck for pr

$1.15 available: In StockQuick Overview: Zhejiang Yifang New Materials, with 20 years of production and processing, international standards, and a daily output of 70 tons.

Is your acrylic sheet production factory a bottleneck for project delays or a guarantee for on-time delivery?

As a project manager, you are well aware that time is money. When a critical acrylic component is delayed in arrival, it can trigger a chain reaction: production lines stagnate, installation teams become idle, and customer satisfaction decreases. When choosing an acrylic sheet production factory, "on-time delivery rate" is a KPI that is more worthy of your attention than "unit price". This article will explore three core competencies of factories that are often overlooked but directly affect project progress.

A well managed factory should be able to provide you with clear visibility of the production process, rather than a 'black box'.

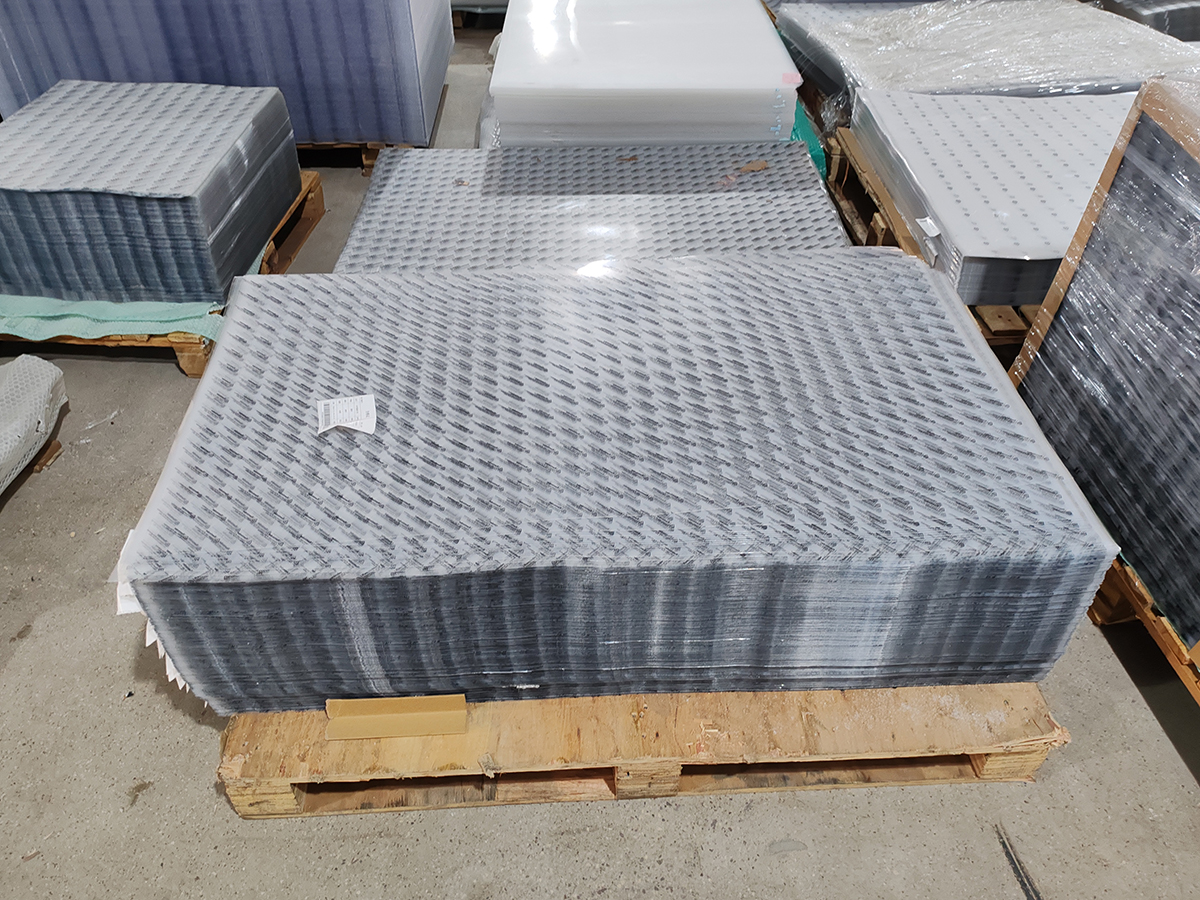

Node update: Professional factories will proactively update you on the progress of key nodes such as cutting, die-casting, curing, quality inspection, and packaging, and even provide on-site photos or short videos. This allows you to accurately control the pulse of the project without the need for repeated reminders.

Transparent production schedule: They dare to share recent production schedules and provide a delivery date based on reality rather than optimistic estimates. This helps you with scientific project planning.

Many factories offer an attractive 'standard lead time', but the following factors can greatly extend it:

Raw material inventory level: Does the factory have sufficient stock of commonly used raw materials? Do we still need to wait until your order is confirmed before making the purchase? We have established a strategic raw material warehouse to ensure that the production of commonly used part numbers can begin immediately.

Quality control process: Rigorous QC requires time. A factory that promises 24-hour shipping may have compromised on quality inspection. We firmly believe that comparing and reworking once is faster. Our process oriented quality inspection system is a 'stabilizer' of delivery time, not a 'variable'.

Please add these questions to the list when evaluating suppliers next time:

What is your average on-time delivery rate? "(Our goal is to achieve over 98%)

What is your communication process if there is a force majeure delay during the production process

Can you provide actual delivery time data for similar scale orders in the past six months

| Compositions | pet、ps、acrylic |

| Styles | 1.22*2.44*3/Customization of various specifications and sizes |

| manufacturer | Yifang |

related products

FREE SHIPPING

Free shipping on all UK orders

FREE EXCHANGE

30 days return on all items

PREMIUM SUPPORT

We support online 24 hours a day

BLACK FRIDAY

Shocking discount on every friday