Acrylic sheet: Your invisible quality guardian, how can we a

$1.15 available: In StockQuick Overview: Zhejiang Yifang New Materials, with 20 years of production and processing, international standards, and a daily output of 70 tons.

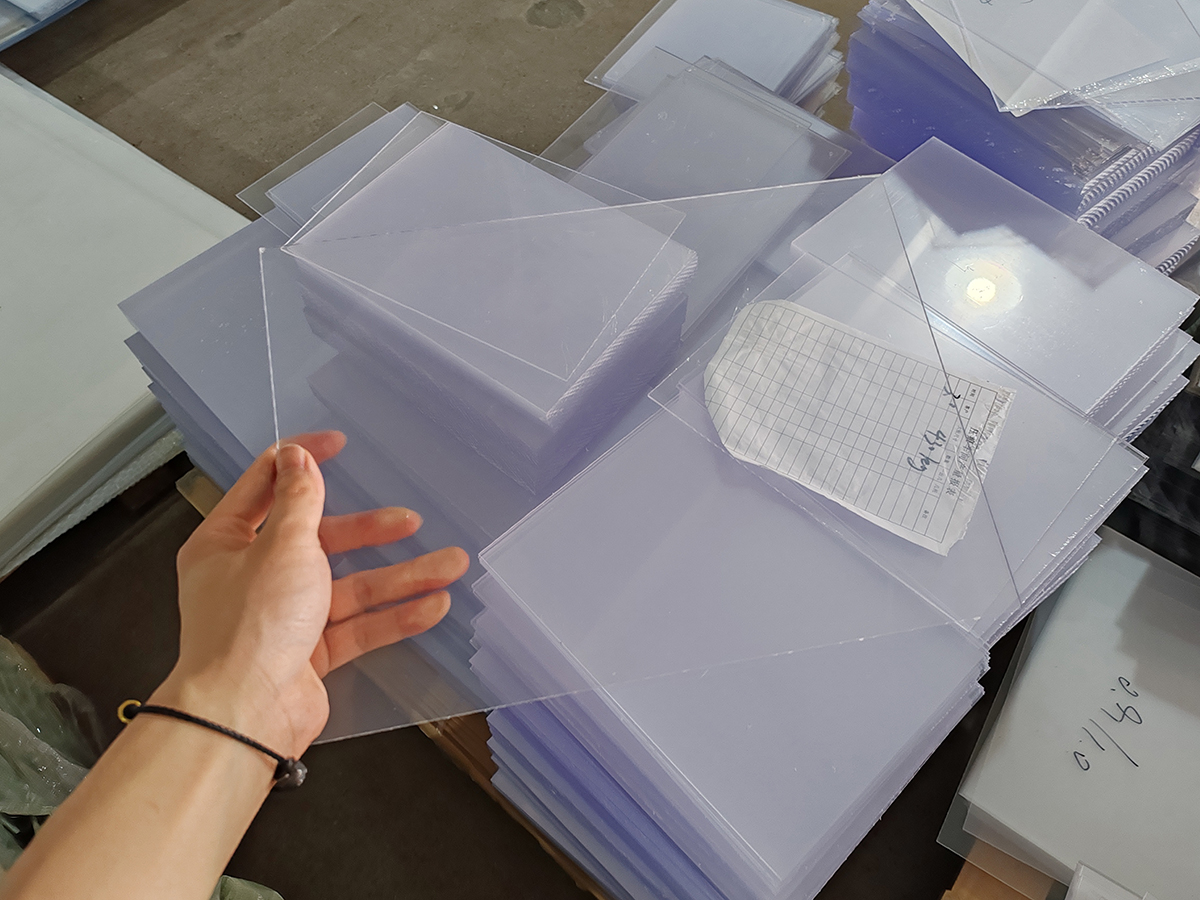

Acrylic sheet: Your invisible quality guardian, how can we achieve a 99.7% unboxing pass rate

As a purchaser, are you tired of the empty slogan of "quality commitment"? When you click on the search for "acrylic sheet production factory prices", what you are really looking for is a partner who can make you sleep peacefully - a partner who internalizes quality as muscle memory, not just certificates hanging on the wall. We believe that excellent quality is not achieved through inspection, but through design and production. This article will take you deep into our factory's "quality black box" and reveal three internal practices that exceed industry standards, ensuring that every sheet you receive is completely trustworthy.

Most factories purchase ready-made PMMA particles, but we choose to control them from upstream.

Exclusive cooperation and batch tracking: We have established strategic partnerships with top global chemical giants, not only to lock in high-quality methyl methacrylate monomers, but also to achieve full batch traceability from petroleum based raw materials to factory boards. Each board can have its' proof of origin 'checked.

Internal pre polymerization and formula optimization: We do not use generic particles. We have our own pre polymerization workshop, where customized additives and colorants are added during the liquid stage based on the intended use of the final product (such as ultra-high impact resistance, super weather resistance, laser specific) to achieve uniform fusion at the molecular level. This ensures a high degree of consistency and predictability in the performance of the board, fundamentally eliminating quality fluctuations caused by differences in raw material batches.

Our production line is more like a precision laboratory than a simple machining workshop.

Full process sensor network: Over 200 sensors collect real-time data from the temperature and pressure of the aggregation kettle, the temperature and humidity curve of the curing chamber, and the duration and gradient of heat treatment. These data are not only used for real-time alarms, but also integrated into our MES (Manufacturing Execution System) to establish independent "digital twin" files for each sheet.

Daily implementation of Statistical Process Control (SPC): Our engineers do not review production reports during daily meetings, but instead analyze SPC control charts. By monitoring the slight deviation trends of key process parameters, we can intervene and adjust before quality issues occur, ensuring stable production control at its optimal state. This forward-looking control is the cornerstone for us to achieve a 99.7% box opening qualification rate.

Our quality inspection department is the most "unpopular" but also the most respected department in the company.

Destructive testing beyond customer standards: In addition to routine size, appearance, and transmittance testing, we randomly select finished products every day for extreme testing, including impact resistance testing far beyond national standards, continuous UV aging testing, extreme high and low temperature cycling testing, etc. We actively 'destroy' our own products to explore their performance boundaries and failure modes, providing a huge safety margin for conventional products.

Rapid iteration of quality feedback: Any customer feedback (even non quality complaints) will be recorded and our 8D problem-solving process will be initiated. The root cause analysis will be directly fed back to the R&D and production departments, and the process documents may have been updated in the next production cycle. Quality is an endless cycle of dynamic improvement for us.

Believe in data, not words. We invite you to propose the most challenging quality performance requirement (such as not cracking after repeated bending at minus 30 degrees Celsius, or withstanding long-term immersion in specific chemicals). Please leave your challenge in the comment section, and our Chief Quality Officer will personally respond and attach our relevant extreme testing data report. Let's start a collaboration based on ultimate trust with facts.

| Compositions | pet、ps、acrylic |

| Styles | 1.22*2.44*3/Customization of various specifications and sizes |

| manufacturer | Yifang |

related products

FREE SHIPPING

Free shipping on all UK orders

FREE EXCHANGE

30 days return on all items

PREMIUM SUPPORT

We support online 24 hours a day

BLACK FRIDAY

Shocking discount on every friday