The biggest risk of color customization is not the price, bu

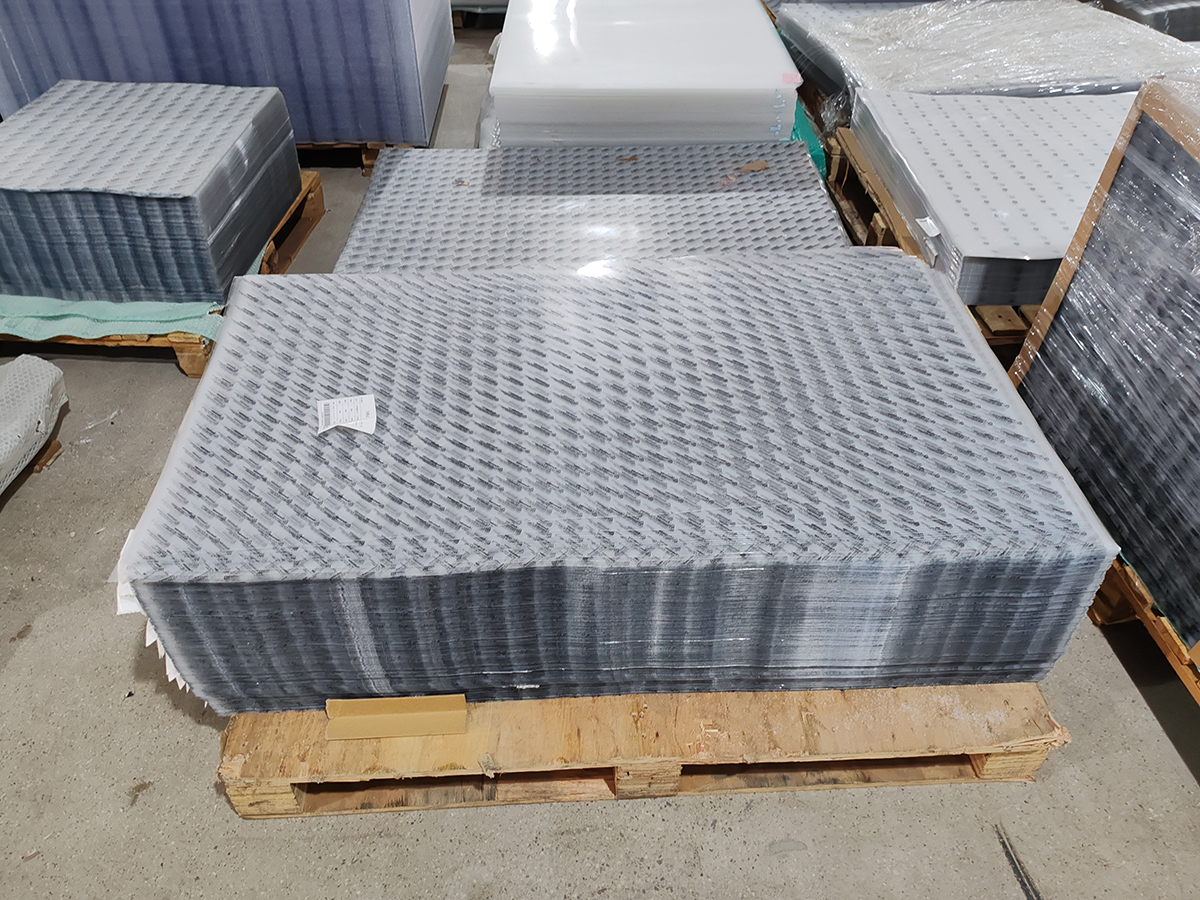

$1.15 available: In StockQuick Overview: Zhejiang Yifang New Materials, with 20 years of production and processing, international standards, and a daily output of 70 tons.

The biggest risk of color customization is not the price, but the failure of "getting it right the first time"

Launching a project that requires custom colored acrylic sheets is exciting, but also comes with great anxiety. If you search for "source price of color acrylic board", you know that the real cost does not lie in the board itself, but in the one-time success of the entire process. A color deviation or discrepancy in effect can mean project delays, budget overruns, and a blow to team morale. Therefore, when choosing the source factory, what you should purchase is a system that maximizes the probability of being "right the first time", rather than just color matching ability.

Your color journey begins with a digital file (Pantone color code, AI design draft), but the factory needs to transform it into a physical world entity. The fault here is the main risk point.

Screen color difference and material performance: Computer screens are luminous (RGB), while panels are reflective (CMYK+texture). The same color code looks completely different on glossy, matte, transparent, and solid substrates.

Our 'physical calibration' process: We will never produce bulk orders solely based on the Pantone number. The standard process is: 1) Create a small-scale physical color palette based on your digital file; 2) Confirm under your actual usage environment lighting (we recommend viewing under different light sources); 3) Fine tune according to your feedback. The cost and time of this step are the most cost-effective investments to avoid catastrophic errors.

The sample you confirmed is flawless, but the bulk color is inconsistent - this is the most classic nightmare. The root cause lies in the loose production control.

Core: Absolute lock of formula and process: After sample confirmation, all parameters such as precise raw material batch, mixing ratio, temperature, and curing time will be encrypted and saved as the "golden formula". During mass production, the system will strictly lock and reproduce all these conditions, supplemented by an online spectrometer for real-time comparison.

The guarantee you receive: The quality inspection report attached with the bulk shipment will include the Delta E value of the color difference between the batch of products and the confirmed sample (usually required to be<1.0, difficult to distinguish with the naked eye). We use data instead of promises.

Colors will 'manifest' differently in different usage scenarios. Without considering this, even if the color itself is accurate, the final effect may still fail.

We will confirm with you the list of key issues before sampling:

Is this board used independently or in combination with other materials (wood, metal, another color of acrylic)?

Is it illuminated internally (such as a lightbox), or does it rely on external ambient light reflection?

Does it need to consider long-term stability under outdoor ultraviolet radiation?

Our scenario based consulting service: Based on your answer, we may suggest adjusting the brightness or saturation of colors, and even recommend adding special effects (such as micro pearl) to achieve the desired visual effect in a specific scene. We are your creative translators and implementation consultants.

| Compositions | pet、ps、acrylic |

| Styles | 1.22*2.44*3/Customization of various specifications and sizes |

| manufacturer | Yifang |

related products

FREE SHIPPING

Free shipping on all UK orders

FREE EXCHANGE

30 days return on all items

PREMIUM SUPPORT

We support online 24 hours a day

BLACK FRIDAY

Shocking discount on every friday